Why Air Separation Equipment Powers Modern Industry

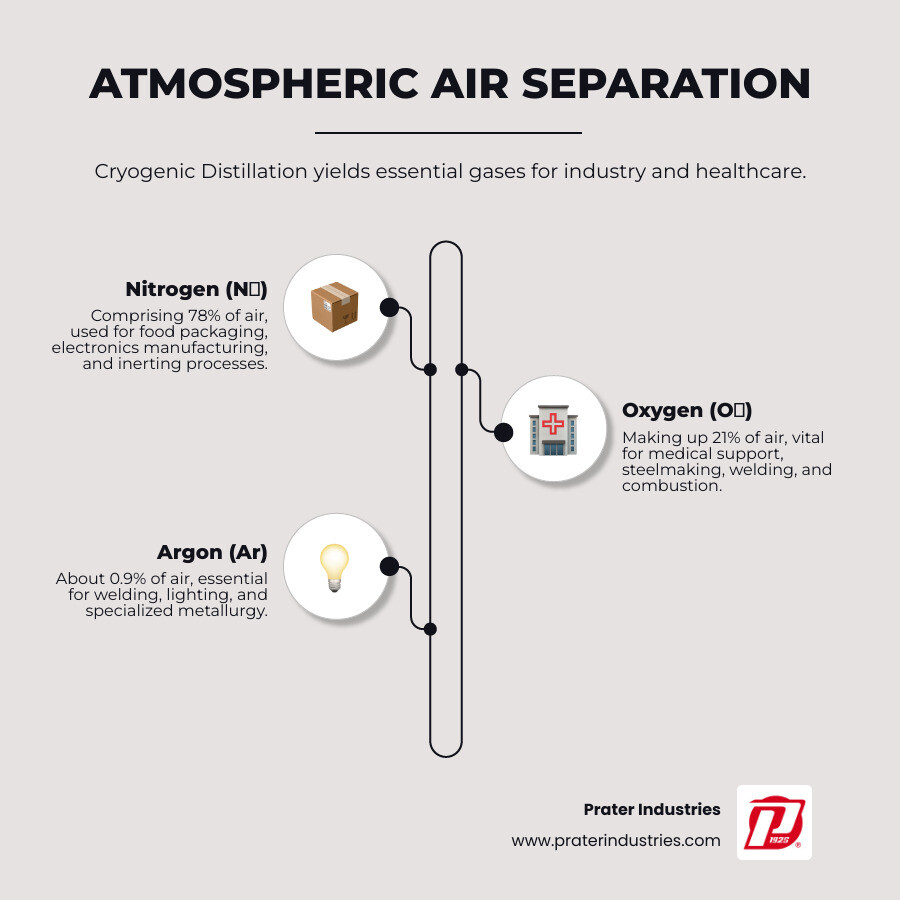

Air separation equipment is industrial machinery that separates atmospheric air into its primary components: nitrogen, oxygen, and argon. These systems, particularly Air Separation Units (ASUs), use cryogenic distillation or non-cryogenic methods to produce high-purity industrial gases at scale.

Quick Answer: What You Need to Know About Air Separation Equipment

- Primary Function: Separates air into nitrogen (78%), oxygen (21%), and argon (0.9%)

- Main Technology: Cryogenic distillation at temperatures as low as -196°C (-321°F)

- Production Scale: From 50 to 7,000+ tons per day

- Purity Levels: Up to 99.95% for oxygen, <1 PPM impurity for nitrogen

- Key Applications: Healthcare, steelmaking, chemical production, food preservation, electronics manufacturing

- Major Advantage: More cost-effective than gas cylinders for large-volume industrial needs

Separating the nitrogen and oxygen in the air we breathe requires specialized equipment operating at extreme temperatures and pressures. Since the first industrial unit was pioneered in 1902, this technology has become essential to modern manufacturing. Today, over 4,000 air separation plants worldwide produce the industrial gases that make everything from medical oxygen to semiconductor chips possible.

For operations managers, understanding air separation equipment reveals how precise separation technology can improve production efficiency. The same principles that separate air molecules at -196°C can be applied to optimize your material processing operations.

How Air Separation Works: The Cryogenic Distillation Process

An Air Separation Unit (ASU) is an industrial facility that separates atmospheric air into its primary components: nitrogen, oxygen, and argon. The goal is to produce these gases in high purity and large quantities for applications ranging from hospital oxygen to steelmaking.

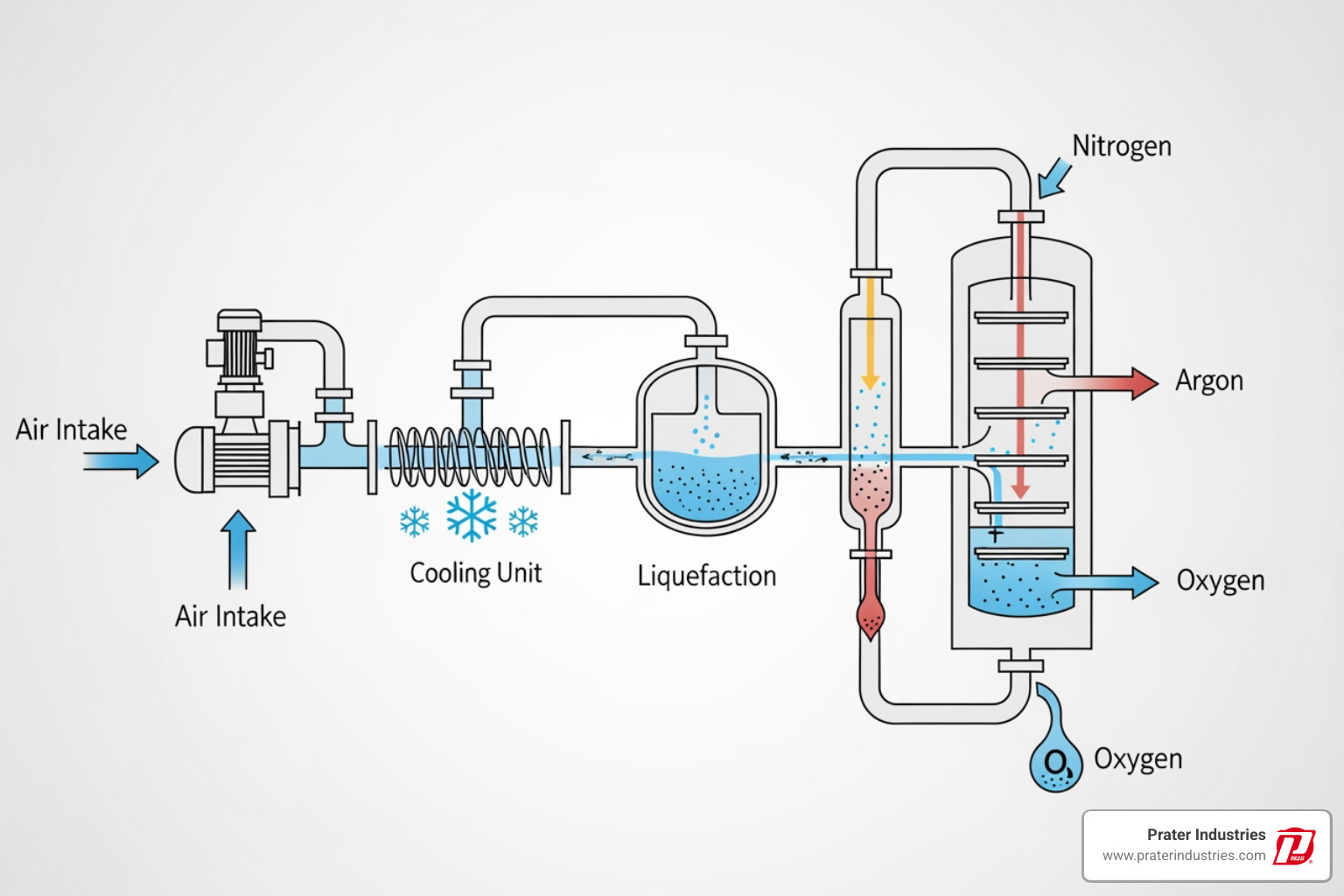

The core technology is cryogenic distillation, a process that exploits the different boiling points of gases. By cooling air to extremely low temperatures, it becomes a liquid that can be carefully separated into its components as it warms.

Cryogenic distillation is a continuous process where air flows in, is transformed through precisely controlled steps, and emerges as separate, high-purity gas streams. This relies on the integration of heat exchangers and distillation columns.

The Five Key Steps of Air Separation

The process unfolds in five stages:

- Compression: Atmospheric air is compressed to a higher pressure, typically between 5 and 10 bar, which is essential for the subsequent cooling stages.

- Air Purification: The compressed air passes through molecular sieves—beds of adsorbent material—that trap moisture, carbon dioxide, and hydrocarbons. These impurities would otherwise freeze and clog the system.

- Cooling: The purified air is cooled in heat exchangers by the outgoing cold product gases. Expansion turbines then rapidly expand the air, causing its temperature to plummet and partially liquefy it. These turbines often help drive the main air compressor, recovering energy.

- Separation: In the distillation columns, the liquefied air is gently warmed. Each component boils off at its unique temperature and is collected separately in a process called fractional distillation.

- Collection: The separated gases—pure nitrogen, oxygen, and argon—are warmed to ambient temperature as they pass back through the heat exchangers, ready for storage and distribution.

The principles of effective separation are universal in many industrial processes. To learn more, our article on air classifier working principles explores these concepts in depth.

The Science of Separation: Boiling Points

Air separation equipment works because each gas has a unique boiling point. By cooling air to a liquid and then carefully warming it, each component can be isolated.

- Nitrogen: With a boiling point of -196°C (-321°F), it's the most volatile and vaporizes first. It's used in food packaging and electronics.

- Argon: Boiling at -186°C (-303°F), this gas is often captured in a dedicated column for use in welding and lighting.

- Oxygen: Having the highest boiling point at -183°C (-297°F), it remains liquid the longest and collects at the bottom of the column. It's vital for medical and steelmaking applications.

These small temperature differences are key to the efficient separation that modern industry relies on.

Types of Air Separation Equipment and Technologies

Choosing air separation equipment involves deciding between two main families: cryogenic and non-cryogenic systems. The right choice depends on required purity levels, production volume, and specific application.

Cryogenic vs. Non-Cryogenic Methods

Cryogenic Air Separation Units are the industrial giants, producing massive volumes of ultra-pure gases. They can achieve oxygen purity up to 99.95% and nitrogen with less than 1 PPM of oxygen impurity, which is essential for sensitive applications like semiconductor fabrication. Cryogenic ASUs are also the only practical method for recovering rare gases like neon, krypton, and xenon.

Non-cryogenic methods are more cost-effective for smaller volumes or when lower purity is acceptable.

- Pressure Swing Adsorption (PSA) uses adsorbent materials (zeolites) to trap nitrogen or oxygen from compressed air. Releasing the pressure frees the gas. These systems are ideal for producing medium-purity oxygen (up to 95%) or nitrogen (up to 99.9%) at small to medium volumes.

- Membrane separation uses selective polymeric or ceramic membranes that allow certain gases to pass through faster than others. This creates nitrogen-rich streams or oxygen-enriched air (25-50% O2). While polymeric membranes are energy-efficient, ceramic membranes can achieve higher oxygen purity (90%+) at high temperatures. Innovations in membrane separation technology continue to advance the field, improving efficiency and expanding applications.

| Method | Purity (Typical) | Flow Rate (Typical) | Energy Use |

|---|---|---|---|

| Cryogenic Distillation | Very High (O2 >99.5%, N2 <1ppm O2) | Very Large (50-7000+ TPD) | Medium to High |

| Pressure Swing Adsorption (PSA) | Medium (O2 ~90-95%, N2 ~95-99.9%) | Small to Medium | Medium |

| Membrane Separation | Low to Medium (O2 ~25-50%, N2 ~95-99%) | Small | Low |

Choosing the Right Air Separation Equipment

Selecting the right equipment requires balancing capacity, purity, budget, and flexibility.

- Modular plants are pre-fabricated units that offer faster installation and lower upfront costs. They are ideal for medium-scale operations or remote locations.

- Custom-engineered plants are designed from scratch for large-scale or highly specific needs, with capacities ranging from 50 to over 7,000 tons per day.

- On-site gas generation systems are popular for smaller volume needs, providing a convenient and reliable local supply.

The economics of air separation are compelling at larger volumes due to economies of scale, with some manufacturers reporting a 19% reduction in total cost of ownership (TCO) over the last decade. Understanding these options allows for smarter operations, much like how advanced air classifiers can solve material separation challenges.

The Impact of ASUs: Applications and Advantages

The gases produced by air separation equipment are an invisible workforce powering countless modern processes, from healthcare to food preservation.

Essential Applications Across Industries

The separated gases from ASUs have remarkably versatile applications:

- Healthcare: Medical-grade oxygen is a lifeline for patients, supporting surgeries and emergency respiratory care.

- Industrial Sector: High-purity oxygen is crucial for steelmaking, where nearly two tons of oxygen are used per ton of steel produced. You can explore more in resources like Innovations in Industrial and Engineering Chemistry. Oxygen is also used for welding and cutting, while argon provides inert atmospheres for precision TIG welding. Nitrogen is a key component in producing ammonia for fertilizers.

- Semiconductor Fabrication: Ultra-high purity nitrogen and argon create the perfectly inert atmospheres required to prevent contamination during the manufacturing of sensitive electronics.

- Food and Beverage: Nitrogen is used to displace oxygen in packaging, preventing spoilage and extending the shelf life of products like coffee and snack foods.

- Energy Sector: Oxygen improves combustion efficiency in power plants and supports technologies like coal gasification.

Key Advantages of Cryogenic ASUs

For high-volume operations, cryogenic ASUs offer compelling advantages over other supply methods like gas cylinders:

- High Purity: They produce oxygen up to 99.95% pure and nitrogen with less than 1 PPM of oxygen contamination, a non-negotiable requirement for medical and electronics applications.

- Scale of Production: ASUs can produce massive quantities of gas (e.g., 500 to 110,000 Nm³/hr of oxygen), creating economies of scale that lower per-unit costs.

- Co-production Capability: A single unit can simultaneously produce oxygen, nitrogen, and argon, improving overall efficiency and cost-effectiveness.

- Rare Gas Recovery: Cryogenic distillation is the only economical method to recover rare gases like neon, krypton, and xenon.

- Long-Term Economics: Despite a substantial initial investment, the long-term operational costs for on-site gas generation are significantly lower than purchasing and transporting gases, making ASUs a strategic asset.

Modern ASU Design, Safety, and Future Trends

The story of air separation equipment is one of continuous evolution since the late 19th century. The first industrial unit appeared in 1902, and by 1910, the double-column system allowed for simultaneous production of pure oxygen and nitrogen. Innovations in heat exchangers, turbines, and control systems have made today's ASUs marvels of engineering efficiency.

Key Design Features for Efficiency and Reliability

Modern ASUs are highly orchestrated systems designed for reliability and low maintenance, principles we value at Prater Industries.

- Integrated Heat Exchangers: These form the heart of ASU efficiency. Cold product gases leaving the system pre-cool the incoming air, recycling "cold" energy and drastically cutting power requirements.

- High-Efficiency Expansion Turbines: These components cool the air through rapid expansion and recover energy to help drive the main air compressor, creating a self-reinforcing efficiency cycle.

- Advanced Process Control Systems: Sophisticated PLC-based systems with user-friendly interfaces enable unattended operation and remote monitoring, allowing engineers to analyze data and troubleshoot issues from anywhere.

These features have led to significant gains, with average ASU power consumption dropping by 15% and total cost of ownership falling by 19% over the last decade.

Safety and Environmental Considerations

Operating air separation equipment requires a focus on safety and responsibility.

- Oxygen Safety: Because oxygen accelerates combustion, robust design, careful material selection, and strict procedures are non-negotiable. Molecular sieves must remove all hydrocarbons from the incoming air to prevent explosion risks in the cryogenic sections. For detailed guidance, see resources like this Information on oxygen safety in plants.

- Explosion-Proof Design: Facilities incorporate multiple layers of protection, including intrinsically safe electrical systems and pressure relief valves.

- Emissions Reduction: Modern ASUs help industries meet environmental targets. Some ASU-equipped steel mills have achieved up to three times fewer emissions, and specialized nitrogen generators can significantly reduce CO2 emissions.

- Compliance Standards: ASUs must adhere to rigorous international standards, including ASME, CE, CSA, and various ISO standards, ensuring safety for workers and the environment.

The Future of Air Separation Equipment

The future of ASUs is focused on sustainability and advanced technology.

- Increased Energy Efficiency: The primary goal remains squeezing more performance from less power through innovations in process design and turbomachinery.

- Integration with Renewable Energy: ASUs are being designed to adapt to intermittent energy sources like solar and wind, helping to decarbonize industrial gas production.

- Advanced Modular Designs: The trend toward modular and containerized units is accelerating, offering faster deployment and greater flexibility.

- Improved Automation and AI: Predictive maintenance and AI-powered optimization are becoming standard, improving reliability and real-time efficiency.

- Growing Demand: Sectors like electronics, clean energy (hydrogen production), and advanced manufacturing in the US and Canada will continue to drive innovation in air separation equipment.

Frequently Asked Questions about Air Separation

Here are answers to common questions about air separation equipment.

What is the primary function of an Air Separation Unit?

An Air Separation Unit (ASU) separates atmospheric air into its core components: nitrogen, oxygen, and argon. These individual gases are valuable in their pure forms for a wide range of industrial and medical applications, from preserving food with nitrogen to enabling welding with argon. An ASU transforms the air we breathe into precisely controlled, ultra-pure gases that power modern industry.

How pure are the gases produced by an ASU?

Cryogenic air separation equipment delivers exceptional purity. These systems can achieve oxygen purity up to 99.95%, suitable for demanding medical and industrial processes. For nitrogen, impurity levels can be less than 1 part per million (PPM). This level of purity is often non-negotiable for applications like electronics manufacturing, where even trace contaminants can cause significant issues.

Are ASUs better than other gas supply methods like cylinders?

For large-volume industrial operations, ASUs are the superior choice. While cylinders may suffice for small or occasional needs, they are inefficient for continuous, high-volume supply. An ASU provides on-site gas generation, eliminating transportation logistics and the risk of supply disruptions. The economies of scale are significant; despite a higher initial investment, the long-term cost per unit of gas is dramatically lower than purchasing delivered gases. This makes an ASU a more cost-effective and reliable solution for major industrial users.

At Prater Industries, we understand that every operation has unique separation needs. Just as ASUs provide custom gas solutions, we deliver reliable, low-maintenance systems for your specific material handling challenges.

Conclusion

Air separation equipment is a quiet industrial hero, essential to modern civilization. From medical oxygen to the nitrogen that preserves food, these systems take ordinary air and separate it with incredible precision, producing ultra-pure gases for the most demanding applications.

The technology continues to evolve, with a focus on greater energy efficiency, integration with renewables, and smarter automation. This points toward a more sustainable industrial future, especially as demand for essential gases grows in sectors like clean energy and advanced manufacturing across the US and Canada.

At Prater Industries, we understand that the fundamentals of separation technology are key to solving industrial challenges. Our commitment to providing low-maintenance, reliable systems reflects the same focus on efficiency and performance seen in modern ASUs. The lessons are clear: precision, efficiency, and the right equipment make all the difference.

Just as ASUs transform air into valuable assets, we help our customers transform their raw materials into precisely what they need.

Explore our range of high-efficiency air classifiers and separation solutions to see how our expertise can benefit your operations.