Cannabis –also known as hemp or industrial hemp–is cultivated for its fiber or edible seeds. Hemp is often confused with the cannabis plant, the source of marijuana and hashish. Although hemp, marijuana, and hashish derive from the same plant species Cannabis and contain Tetrahydrocannabinol (THC), a psychoactive compound, hemp has only smaller amounts of THC compared to marijuana or hashish.

As the name implies, industrial hemp is an essential raw material for many industrial products. It has wide-ranging applications in textiles, footwear, food, paper, rope, biofuel, and even bioplastics.

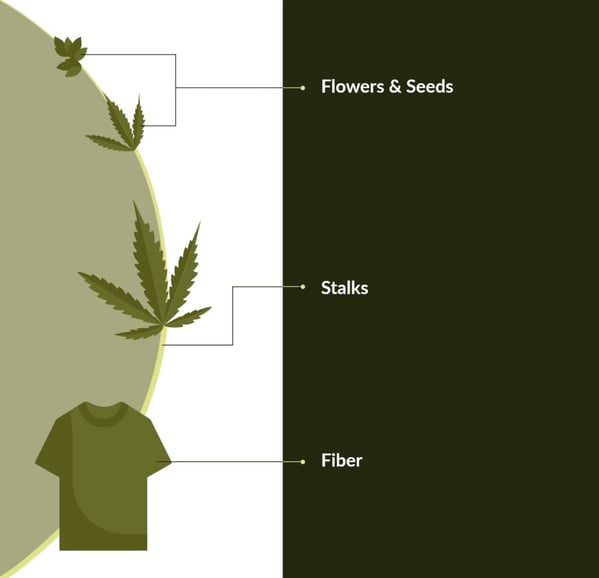

Every part of the hemp plant can be processed and made into an industrial hemp product, from the roots to the leaves. Therefore, the harvesting methods and processing equipment are used according to the hemp plant's part and the end product.

Let’s look at some of the equipment used for processing hemp on an industrial scale.

Flowers and Seeds

Getting the harvesting time right for hemp flowers and seeds is tough because different flowers and seeds mature at varying rates, even on the same plant. So the challenge of harvesting hemp is to do it without losing flowers and seeds.

It is vital to handle hemp seeds carefully, and matured seeds should be removed from the flower heads. On top of that, since these whole hemp seeds have hard shells, they must be dehulled before industrial use.

Dehulling the hemp seeds was carried out manually, making it time-consuming and labor-intensive. Today, hemp processing equipment like hemp seed shelling machines and bucking machines, also known as de-budders or de-stemmers, speed up these processes.

Stalks

The stalk is one of the most valuable parts of the hemp plant for making rope, textiles, paper, insulation, and building materials. Sometimes, when the hemp plant is harvested only for its flowers and seeds, the remaining leaves and stalks will turn into waste. But the industrial hemp product manufacturer can use this hemp waste to make fibers, textiles, or ropes. In addition, it can be fermented and turned into hemp ethanol or biofuel.

Generally, the stalks of the hemp plants go through decortication and retting processes during industrial production. After decortication, it is taken through the scutching process. Scutching, which was once a manual process, is carried out by a machine known as a scutcher.

Fiber

The hemp decortication process takes up a significant portion of the hemp fiber processing. So manufacturing hemp products requires cutting-edge technology to streamline decortication. A modern decorticator can process tons of industrial hemp in an hour and turn them into a wide variety of hemp products. In addition, it can separate the fiber from the stalks and remove resins and gums from the fiber through post-processing.

A decorticator separates the plant's hurds from the bast fiber. Hemp pellets are used to produce animal feeds and heating products. Manufacturers use hemp pelletizer machines to make hemp pellets.

Similar to hammer mills and bucking machines, equipment such as lump-breakers, rotor mills, and fine grinders are used in industrial hemp manufacturing, depending on the input size of the raw materials and desired output size of the end product.

Hemp Processing Equipment from Prater

At Prater Industries, we can design and build custom processing equipment to meet your specific hemp processing needs. In addition to tailor-made solutions, our deck screeners, grinders, lump breakers, and hammermills can be repurposed to process hemp at an industrial scale. Contact us to learn more about how our machinery can help improve hemp processing efficiency.