Why Industrial Lump Breakers Matter for Your Process

Industrial lump breakers solve one of the most common headaches in bulk material processing: clumped, agglomerated material that refuses to flow smoothly through your production line.

What is an Industrial Lump Breaker?

An industrial lump breaker is a machine that breaks down clumps and agglomerates in bulk materials using rotating blades against stationary combs. Here's what you need to know:

- Primary function: De-agglomerates clumped materials and restores free-flowing properties

- Key mechanism: Rotating shaft with breaker bars that work against fixed combs or grids

- Main types: Single-shaft (for friable materials) and dual-shaft (for tough lumps)

- Common applications: Chemical processing, food production, pharmaceuticals, minerals, and agriculture

- Key benefits: Prevents blockages, ensures consistent feed rates, and improves downstream processing

Whether you're dealing with compacted powders from storage, moisture-induced caking, or oversized particles that need gentle reduction, a lump breaker restores your material to its proper particle size range.

This means better material flow, fewer production stoppages, and more consistent product quality throughout your process. The right lump breaker eliminates bridging and ratholing in hoppers, protects downstream equipment from damage, and keeps your operation running smoothly.

Let's explore the different types of lump breakers available and how to choose the right one for your specific materials and process requirements.

How do Industrial Lump Breakers Work?

Material clumping is a frustrating reality in bulk solids handling. During storage or transport, materials like chemicals, food ingredients, and minerals can agglomerate due to moisture, compression, or static. This results in lumps that won't flow, causing equipment stoppages and production delays.

This is where an industrial lump breaker excels. As a de-agglomeration specialist, it breaks stubborn clumps back into free-flowing material. The mechanism is simple: rotating blades work against stationary combs to break agglomerates without creating excessive fines. The result is improved material flow, which improves the performance of all downstream equipment. Feeders, mixers, and packaging lines run more smoothly and efficiently.

The Core Function: Breaking Down Agglomerates

The core function of a lump breaker is material delumping. It performs size reduction with a specific purpose: crushing oversized particles and clumps just enough to restore the material's intended particle size and flowability. This is not the same as pulverizing material into a fine powder. By restoring flowability, lump breakers prevent common flow problems like bridging and ratholing in hoppers and bins. Preventing blockages not only avoids downtime but also improves product quality by ensuring downstream equipment receives a steady, predictable feed.

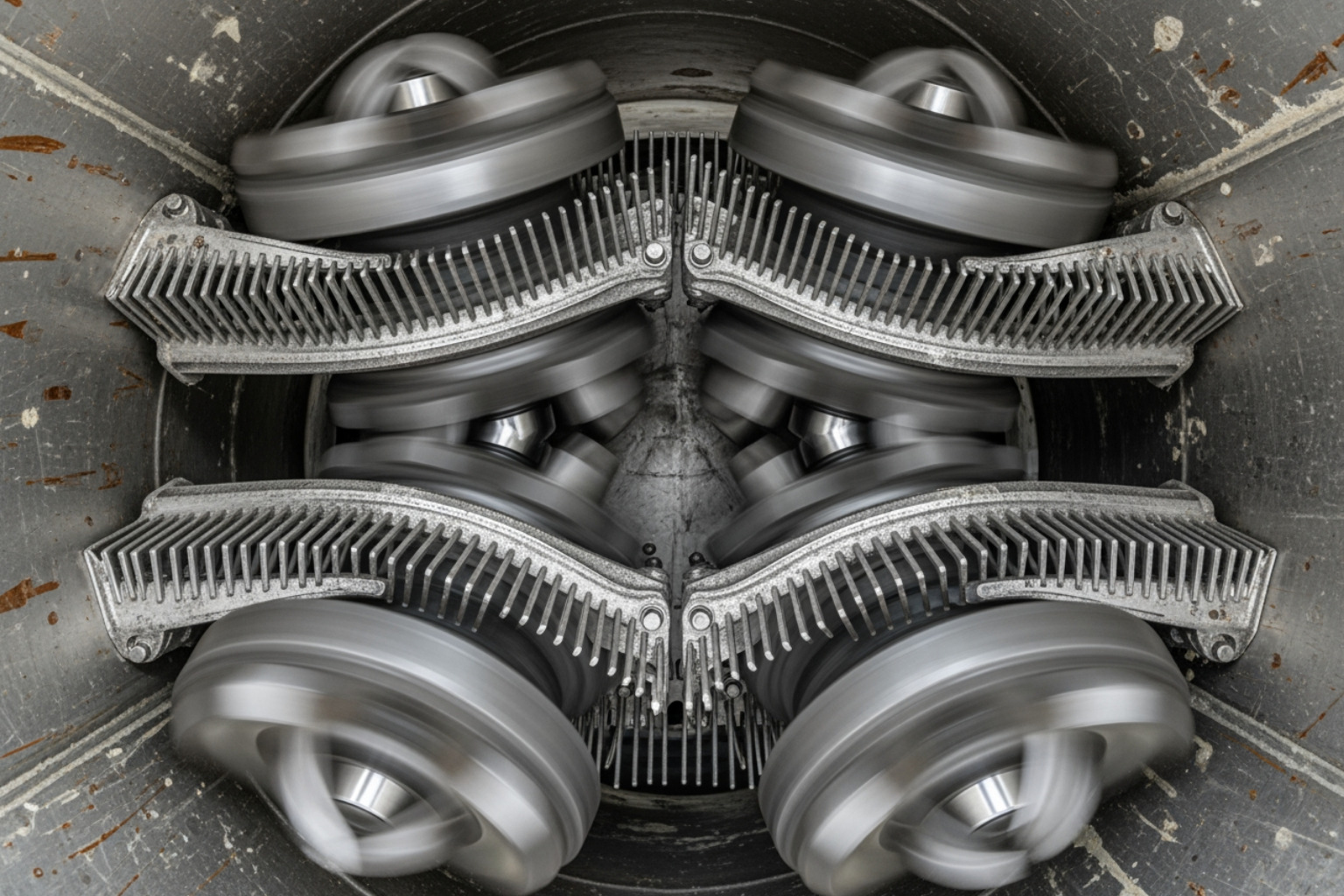

Inside the Machine: The Breaking Mechanism

Open up a lump breaker and you'll find a straightforward mechanism. Material enters the chamber and encounters rotating shafts fitted with breaker bars or blades. These spinning components work against fixed combs or grids, creating a breaking action that combines both impact force and shear force. As lumps pass through, they get caught between the moving and stationary elements, breaking apart compressed or caked materials.

The Dynamics of Impact and Shear

Material enters the chamber and encounters rotating shafts fitted with breaker bars or blades. These spinning components work against fixed combs or grids, creating a dual-action breaking process:

- Mechanical Impact: The initial strike of the blade shatters brittle or "friable" lumps upon contact.

- Tangential Shear: As the material is pulled through the narrow gap between the moving blade and the stationary comb, it undergoes intense shearing forces that tear apart compressed or "caked" fibers.

Preserving Particle Integrity

Unlike a grinder, which uses high-speed friction to create new, smaller particles, a lump breaker is designed to be "gentle" on the base material. The clearance between the rotating and stationary elements is carefully calibrated to ensure that once a lump is reduced to its natural grain size, it passes through the discharge grate immediately. This prevents over-processing and ensures the final product retains its required characteristics.

Engineered for Continuous Flow

Every component, from the shaft seals to the blade geometry, is built for the long haul. These low-maintenance systems are designed to operate under "choke-feed" conditions, meaning they can handle a surge of material without stalling.

Because different materials possess different "clumping strengths," these internal mechanisms are typically configured into two primary designs...

Types of Lump Breaker Machines

Not all lumps are created equal, and neither are the machines that break them. Choosing the right industrial lump breaker is like selecting the right tool for any job: you need to match the machine's capabilities to your material's specific challenges. Some materials form light clumps, while others create rock-hard cakes. Understanding your material is key to selecting the right breaker.

Here's a quick comparison of our most popular industrial lump breaker designs:

| Feature | Single-Shaft Breakers | Dual-Shaft Breakers |

|---|---|---|

| Capacity | Lower to medium throughput | High throughput |

| Material Type | Friable, less dense, moderately agglomerated | Hard, tough, sticky, heavily compacted |

| Applications | Powders, granules, flakes, light cakes | Large blocks, heavy cakes, frozen materials, sticky substances |

| Breaking Action | Impact and shear, gentler reduction | Aggressive crushing, high-torque shearing |

| Maintenance | Generally simpler, fewer moving parts | More robust, designed for demanding conditions |

Single-Shaft Breakers

Best For: High-Speed Processing of Friable Materials

If your material crumbles under finger pressure or "shatters" upon impact, a single-shaft design is typically the most efficient choice. By utilizing a single high-speed rotor against a fixed grid, these units provide a high "open area" for material to pass through quickly. This prevents over-processing and heat buildup, which is critical for temperature-sensitive food powders or chemical flakes.

- Pro-Tip: These are the "go-to" for retrofitting existing gravity-fed lines where vertical space is limited.

Dual-Shaft Breakers

Best For: High-Torque Reduction of Stubborn Agglomerates

When lumps get serious, so do we. Dual-shaft industrial lump breakers are heavy-duty machines for materials that resist gentler methods. They feature two counter-rotating shafts with intermeshing teeth or blades, creating a powerful breaking action.

When materials are "plastic" (pliable but tough) or heavily compacted into solid blocks, impact alone isn't enough. Dual-shaft breakers operate at lower speeds but with significantly higher torque. The intermeshing teeth create a "self-feeding" action, literally pulling large masses into the breaking zone.

This design is essential for materials that tend to "bridge" or sit on top of a single rotor. By using counter-rotating forces, the machine ensures that even sticky or frozen products are forced through the shear points rather than just spinning in the chamber.

Sanitary Design Breakers

Compliance-Ready Engineering

For food and pharmaceutical lines, the breaking mechanism is only half the story; the other half is cleanability. While standard units focus on durability, our sanitary models prioritize the elimination of "harborage points"—microscopic areas where material can collect, and bacteria can grow.

To meet stringent FDA and USDA standards, these units feature:

- High-Grade Materials: We replace standard carbon steel with polished 304 or 316L stainless steel, ensuring surfaces are non-reactive and corrosion-resistant.

- Hygienic Internal Geometry: By eliminating internal threads, pits, and sharp corners, we ensure that no material remains trapped after a production run. Smooth, continuous welds are ground to a mirror finish to prevent particle buildup.

- Rapid Sanitation: We utilize quick-release hardware and tool-free disassembly to support "clean-out-of-place" (COP) workflows. This focus on accessibility allows your team to perform a full teardown and wash-down in minutes, not hours, significantly reducing downtime between batches.

To learn more about how we support these critical industries, visit our page on sanitary processing equipment. We combine powerful de-agglomeration with the cleanliness your process demands.

Key Factors for Selecting an Industrial Lump Breaker

Selecting the right industrial lump breaker is a critical decision that affects your production efficiency and bottom line. The best results come from a careful analysis of your material, process requirements, and operational environment. We always start by understanding your specific situation to ensure you get a machine that works reliably for years.

Matching the Breaker to Your Material

Your material's properties determine the ideal industrial lump breaker. A common mistake is choosing a machine without a full analysis of the material. Key factors include:

- Material friability: How easily the material breaks apart. This often dictates whether a single- or dual-shaft design is needed.

- Moisture content: Wet or sticky materials require special designs to prevent buildup.

- Abrasiveness: Abrasive materials like silica need harder-wearing components to extend equipment life.

- Bulk density: This affects the motor power and throughput capacity.

- Feed size: The maximum lump size determines the required inlet dimensions and breaking capacity.

Understanding these bulk solid properties is essential for effective processing. For a deeper dive into powder characterization and handling, see this helpful guide on understanding key powder properties from AIChE. We use this knowledge to match customers with the right equipment.

Sizing and Customization for Your Process

A lump breaker must fit your production line, not the other way around. We customize our equipment to your process.

- Inlet and outlet configuration: We design flanges and transitions to integrate with your upstream and downstream equipment, like bulk bag dischargers or pneumatic conveyors.

- Drive options: We offer standard and explosion-proof motors to meet your facility's safety requirements, especially in environments with combustible dust.

- System integration: Our engineers ensure our lump breakers work harmoniously with your existing hoppers, conveyors, and other machinery.

- Dust control options: We provide dust-tight housings and connections for dust collection systems to maintain a clean, safe facility.

- Variable speed control: This allows you to adjust breaking speed on the fly to optimize performance for different materials without stopping production.

Based in Bolingbrook, IL, we provide these custom solutions to customers across the US and Canada, providing a solution that genuinely improves how your entire operation runs.

Common Industries and Applications

The versatility of the industrial lump breaker makes it an indispensable tool across a wide array of industries. From ensuring the purity of pharmaceuticals to improving the flow of animal feed, these machines deliver consistent performance where it matters most.

We see our lump breakers making a significant impact in:

- Chemical processing: Breaking down compacted chemicals, pigments, and resins.

- Food and beverage: De-agglomerating sugar, flour, spices, frozen foods, and other ingredients.

- Pharmaceuticals: Ensuring uniform powder consistency for tablet pressing and encapsulation.

- Minerals and mining: Reducing oversized mineral aggregates or caked raw materials.

- Agriculture: Breaking up animal feed, fertilizers, and grain products.

- Waste processing: Conditioning certain types of waste for further processing or disposal.

Essentially, any industry that handles bulk powders, granules, or flakes can benefit from an industrial lump breaker.

Enhancing Safety and Efficiency in Bulk Solids Handling

The benefits of a lump breaker extend far beyond simply breaking clumps. They are critical tools for enhancing both safety and overall efficiency in bulk solids handling.

Consider these crucial advantages:

- Preventing bridging and ratholing: A lump breaker eliminates these common hopper flow problems, preventing costly production stoppages.

- Ensuring consistent feed rates: Uniform particle size allows for precise metering and dosing, which is vital for product quality.

- Reducing combustible dust hazards: A properly sized lump breaker can lower dust generation during breaking, mitigating the risk of combustible dust incidents.

- Protecting downstream equipment: Pre-conditioning material prevents oversized lumps from damaging sensitive equipment like feeders and mixers, reducing maintenance costs.

- Metering accuracy: Consistent material flow ensures accurate measurement and precise product formulations.

In our facilities across Illinois and serving customers throughout the US and Canada, we consistently see how the integration of an industrial lump breaker leads to smoother operations, safer working environments, and a significant return on investment.

Frequently Asked Questions about Lump Breakers

Over the years, we've had countless conversations with customers about industrial lump breakers. Here are the answers to the questions we hear most often:

What is the difference between a lump breaker and a crusher or grinder?

While the terms are sometimes used interchangeably, these machines have distinct purposes.

- An industrial lump breaker is for de-agglomeration. It restores a material's original, free-flowing particle size by breaking up lumps and cakes formed during storage or transport. It fixes clumping without fundamentally changing the material's properties.

- A crusher performs primary size reduction. It uses high force to break down large, hard materials like rocks or ore into smaller, more manageable pieces.

- A grinder is used for fine particle creation. It takes smaller particles and reduces them further into a fine powder, often to micron sizes, to meet specific product requirements.

In short: a lump breaker restores flowability, a crusher handles coarse reduction, and a grinder creates fine powders.

How do I maintain an industrial lump breaker?

Our industrial lump breakers are designed for reliability and low maintenance, but regular care ensures optimal performance. Key maintenance tasks include:

- Routine Inspection: Regularly check for unusual noises, vibrations, and signs of wear on blades, combs, and screens.

- Bearing Lubrication: Follow the recommended schedule and use the proper lubricants to prevent premature wear.

- Blade and Comb Replacement: These are wear parts, especially with abrasive materials. Our designs allow for quick and simple replacement to minimize downtime.

- Cleaning: Follow cleaning procedures based on your material, especially for sanitary applications or sticky products, to prevent buildup and maintain efficiency.

Our commitment to your process continues long after installation. We offer a full suite of aftermarket support, including rapid-ship replacement parts and expert on-site maintenance. Whether you need a precision-machined component or a local service technician for a system tune-up, our North American support network has you covered.

Can an industrial lump breaker handle wet or sticky materials?

Yes, but it requires specific engineering. Wet and sticky materials tend to cling to surfaces, which can cause buildup and reduce efficiency. We address this with several solutions:

- Material-Specific Designs: We customize blade configurations, shaft speeds, and internal clearances to prevent material accumulation.

- Non-Stick Coatings: Applying specialized coatings to internal surfaces can dramatically reduce adhesion, improving flow and simplifying cleaning.

- Self-Cleaning Mechanisms: Some designs incorporate features to actively prevent material buildup on the breaking elements.

Because every material is different, we emphasize the importance of material testing. By testing your material in our lab, we can identify the exact features and configurations needed, eliminating guesswork. We can design a custom solution to handle even the most challenging wet or sticky materials.

Conclusion: Achieve Uniform Particle Size with the Right Partner

Here's the bottom line: in bulk material processing, consistency is essential. An industrial lump breaker delivers significant value by increasing efficiency, improving product quality, and ensuring process reliability throughout your operation.

Investing in the right lump breaker means no more frustrating downtime from bridged hoppers, no more damage to downstream equipment, and no more inconsistent feed rates. These are significant issues that can derail production schedules, inflate maintenance costs, and impact your bottom line.

We've built our reputation on understanding these challenges. Our low-maintenance systems are engineered from the ground up to run day after day with minimal intervention. When you do need support, our expert on-site technical services ensure you're never left struggling. Whether you're in Bolingbrook, IL, or anywhere across the US and Canada, our team has your back.

Every process has unique demands, which is why we don't offer off-the-shelf solutions. We work with you to understand your materials and requirements. Our engineers have decades of experience in size reduction and are ready to solve your material handling challenges.

Don't let stubborn lumps control your production schedule. You deserve a partner who understands that your success depends on consistent, reliable performance. We're ready to put our experience to work for you, finding the perfect size reduction solution that fits your operation.

Ready to take the next step toward smoother material flow? Contact our experts to find your size reduction solution today. Let's discuss your challenges and explore how the right industrial lump breaker can transform your operation.