Understanding the operational nuances is pivotal in choosing between Rotormills and Hammermills for material processing. The primary contrast lies in how these machines reduce particle size during material handling. While Hammermills depend on impact force from a spinning rotor, Rotormills utilize centrifugal force and high-velocity air currents to propel particles across a corrugated lining. This attrition process sets the scene for a detailed comparison between these two mill types.

A Comprehensive Comparison: Rotormills vs. Hammermills

To determine the ideal mill for processing specific material or executing particular applications, assessing the operational methods of each machine is crucial. When weighing rotormills against hammermills, a significant disparity lies in how they reduce particle size during material handling operations. Hammermills predominantly rely on impact force from a spinning rotor to decrease particle size, while Rotormills leverage a similar rotor to create centrifugal force and high-velocity air currents for accelerating particles across a corrugated lining. The attrition occurs as these particles abrade against each other and the corrugated lining.

The benefits of utilizing a rotormill include:

- Facilitating the continuous processing of fine materials with high throughputs.

- Eliminating the need for screens that may cause blockages or premature wear.

- Providing a solution for reducing a broad range of materials, including those that are not easily crushable or abrasive.

- Handling various material types.

- Cutting down on processing time and costs as the mill can perform multiple operations simultaneously.

- Operating without the requirement for a specialized base.

The grinding chamber comprises three sections. The lower section encompasses a fan blade to receive and disperse the material into the middle section, featuring a gap between the rotor and corrugated lining. The length and circumference of this gap determine the grinding residence time. As air transports material upward, ground particles enter the third upper section, where a plenum or discharge pipe enables the extraction of ground particles to a downstream product collector.

This pulverization process, coupled with continuous airflow, diminishes heat within the machine. The amalgamation of impact and moving air, with adjustable speed, enables the swift processing of various materials. It also facilitates milling thermosensitive products without necessitating an additional cooling process outside the lower section's fan.

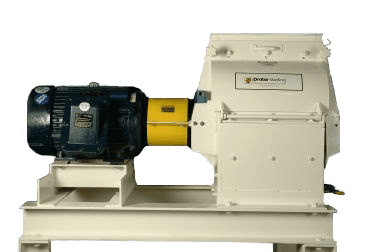

Initially employed for processing grains, Hammermills are now utilized across a wide array of applications. These mills also encompass a grinding chamber that receives raw product through a rotary screw or feeder towards the mill's upper portion.

Hammermills utilize hammers to strike the material against stationary plates within the grinding chamber. The ensuing impact reduces the particle velocity, guiding the particles into the hammers' trajectory to generate maximum force. The material then moves to the bottom of the grinding chamber against a sizing screen, through which appropriately sized particles pass. Some hammermills utilize blowing air instead of screens for classification. The final product exits beneath the mill and is conveyed mechanically or pneumatically for packing or further processing.

Hammermills are best suited for applications where:

Hammermills are best suited for applications where:

- Throughput adjustments are infrequent.

- Breaking down grain fibers is essential.

- Energy costs are not a concern.

- Mixing additives or other applications where particle variation is acceptable.

Hammermills are renowned for their cost efficiency, straightforward design, and simplified maintenance. While they produce uniform particle shapes, the particle sizes can vary significantly. In comparison to rotormills, hammermills generate less heat. Both technologies can handle materials prone to dust explosions, necessitating additional safety measures. Consequently, this elevates energy consumption and maintenance expenses.

A Comparison of Their Primary Distinctions

Rotormills, also called long gap mills, feature an elongated ringlike gap between the mill's inlet and outlet. This setup enables material reduction through attrition as particles collide. Conversely, hammermills rely solely on the impact force principle. The broader range of particle sizes produced by hammermills results in a more diverse particle assortment. However, factors such as screen size, rotor speed, and hammer configuration in hammermills also influence particle size distribution.

Due to their precise particle size distributions, rotormills are preferred over hammermills for precision applications. These applications encompass deagglomeration and fine grinding for chemical processing, food ingredient processing, pigment manufacturing, and mineral processing. Nonetheless, the versatility of hammermills renders them valuable across these same industries and in agriculture, biomass processing, pharmaceuticals, and other sectors.

Maximize Material Handling Efficiency

Businesses in the material handling sector exploring the distinctions between rotormills and hammermills for their operations can leverage Prater Industries' expertise. With expertise in both rotormills and hammermills, Prater possesses comprehensive knowledge of all facets of material processing. For insights on rotormills versus hammermills and details on our offerings, please contact our representatives at Prater today.