Why Choosing the Right Industrial Hammer Mill Matters

An industrial hammer mill is a high-impact machine for particle size reduction, designed to grind, crush, and pulverize materials into smaller, uniform sizes. Choosing the wrong one can lead to inconsistent sizing, equipment breakdowns, and costly downtime. Here's what you need to know when comparing hammer mills:

Key Features to Compare:

- Mill Type - Full-screen, gravity discharge, or pneumatic systems

- Speed Range - 1,500-1,800 RPM for coarse grinding; 3,000-3,600 RPM for fine grinding

- Screen Configuration - Interchangeable perforated screens control final particle size

- Hammer Design - Swing-type or rigid blade hammers impact material differently

- Power Range - Available from 3 HP to 400+ HP depending on throughput needs

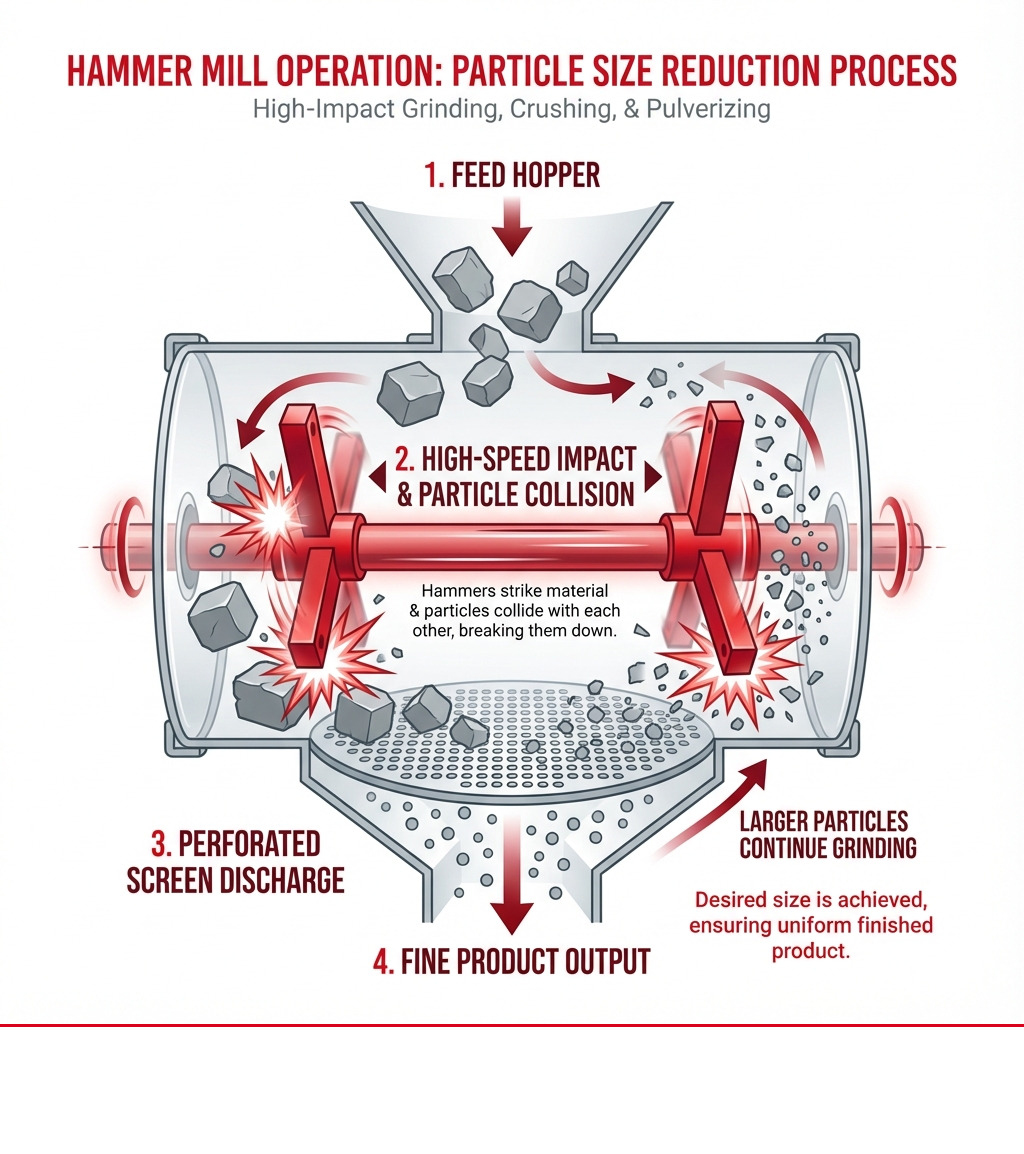

The basic design is simple: material enters a grinding chamber where high-speed rotating hammers strike and break it down. Particles remain until they are small enough to pass through a discharge screen.

However, this simplicity is deceptive. The same design can process everything from fishmeal to coal to wood chips, but only if configured correctly. Variables like rotor speed, hammer type, and screen size all affect final product quality and efficiency.

With over 90 years in the industry, companies like Prater have sold thousands of hammer mills for agriculture, recycling, chemicals, and food processing. Yet many operators struggle to match the right mill to their material.

This guide will help you compare the major types of industrial hammer mills, understand their specific applications, and select the right equipment for your operation.

What is an Industrial Hammer Mill and How Does it Work?

At its core, an industrial hammer mill is a robust machine engineered for particle size reduction. It uses rapidly rotating hammers to pulverize substances, changing larger raw materials into smaller, consistently sized particles. This process is crucial for countless applications, from preparing animal feed to recycling electronic waste.

The working principle revolves around high-speed impact. Material is fed into a grinding chamber where a rotor with multiple hammers spins at high velocity. The hammers strike the material repeatedly, breaking it down. Particle-on-particle attrition also contributes as fragments collide with each other and the mill's interior. The material is ground until it is fine enough to pass through a perforated screen at the bottom or periphery of the chamber, ensuring a uniform finished product.

Our understanding of this process allows us to optimize hammer mills for a vast array of materials. For a deeper dive, explore Understanding the Working Principle of Hammer Mills.

Primary Components Explained

To appreciate the functionality of an industrial hammer mill, it helps to understand its components:

- Feed Hopper: Introduces raw material into the mill. Its design varies depending on the material and feeding method.

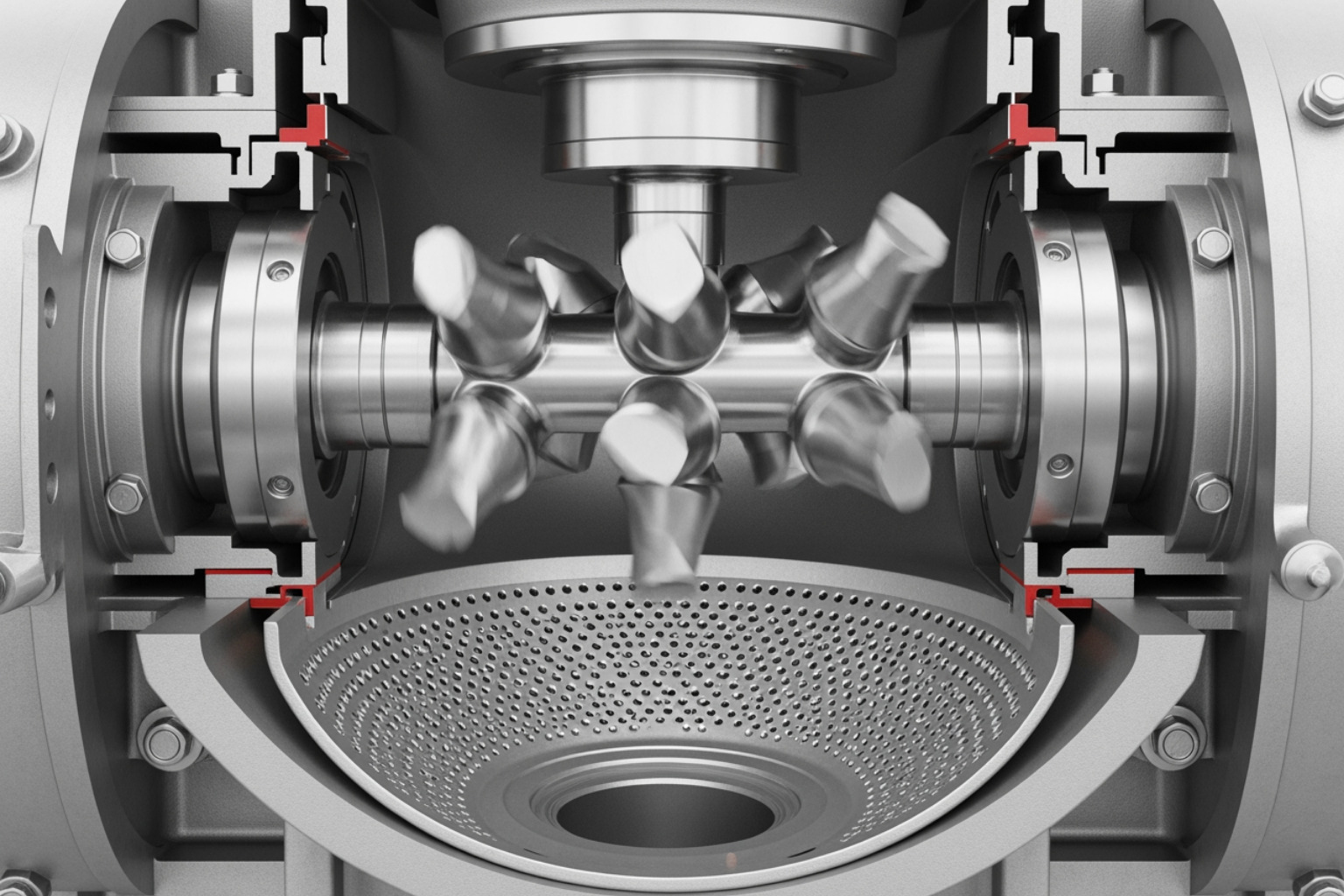

- Rotor Assembly: The heart of the mill, this consists of a central shaft with attached hammers, driven by a motor at high RPMs.

- Hammers: The primary impact tools. They can be swinging (pivoted to reduce damage from tramp metal) or rigid blade (fixed for more aggressive grinding and finer results).

- Perforated Screens or Grates: Located at the discharge point, these have specific hole sizes that determine the maximum size of exiting particles.

- Grinding Plates/Liner Plates: Replaceable, wear-resistant plates that line the grinding chamber, protecting the housing and aiding the grinding action.

- Drive Motor: A powerful electric motor, from 3 HP to over 400 HP, provides the rotational force for the rotor.

- Mill Housing: The robust outer casing that encloses all internal components and contains the grinding process.

For comprehensive details, refer to our Hammer Mill Manual (PDF).

How Particle Size is Controlled

An industrial hammer mill offers several ways to achieve precise particle size:

- Rotor Speed (RPM): This is a significant factor. Higher RPMs (3,000-3,600 rpm) mean more forceful impacts, leading to finer particles, while lower RPMs (1,500-1,800 rpm) produce coarser results.

- Hammer Configuration: The number, size, and orientation of the hammers influence the grinding action and are chosen based on the material's properties.

- Screen Perforation Size: The openings in the discharge screen are the ultimate gatekeepers. Smaller openings mean only finer particles can pass through.

- Feed Rate: A controlled, consistent feed rate prevents overloading, which can reduce grinding efficiency and lead to a coarser, less uniform product.

- Material Properties: The material's inherent characteristics—such as hardness, friability, and moisture content—heavily influence the mill's performance.

By adjusting these variables, we can achieve precise particle size control, often to levels smaller than 10 US mesh (<0.08"). See these controls in action by watching our Prater Hammer Mill Demonstration.

Comparing Types of Industrial Hammer Mills

When selecting an industrial hammer mill, one size doesn't fit all. Various designs are optimized for specific materials, particle sizes, and operational needs. Understanding these distinctions is key. We'll explore three main types: Full-Screen, Gravity Discharge, and Pneumatic Discharge mills.

| Feature | Full-Screen Hammer Mill | Gravity Discharge Mill | Pneumatic/Air-Swept Mill |

|---|---|---|---|

| Design Principle | Maximizes screen coverage around rotor | Material exits via gravity through bottom screen | Integrated air system to draw material through screen |

| Typical Applications | Feed, biomass, agricultural products, chemicals | Abrasive materials, aggregates, minerals, coarse grinding | Heat-sensitive materials, fine powders, light materials |

| Particle Size Range | Fine to medium, uniform | Coarse to medium | Very fine, often micron-sized |

| Efficiency | High, especially for uniform sizing | Robust, good for high-density materials | High for fine grinding, excellent for material conveyance |

| Material Handling | Efficient for various densities | Best for dense, free-flowing materials | Ideal for light, fluffy, or heat-sensitive materials |

| Dust Control | Good, often integrated with collection systems | Requires external dust collection | Integrated dust control, material conveyed by air |

This table provides a quick overview, but let's dig deeper into each type.

Full-Screen Hammer Mills

Full-Screen hammer mills are engineered to maximize the screen area surrounding the rotor, often covering 300 to 360 degrees of the grinding chamber. This extensive coverage offers several advantages:

- High Efficiency: By utilizing nearly 100% of the screen area, these mills process material more rapidly, reducing the time needed to achieve the desired particle size.

- Uniform Particle Size: The design often incorporates distinct grind-and-release zones. This optimized flow path helps ensure a remarkably uniform end product.

- Longer Lifespan: With a larger screen area, wear is distributed more evenly, which can contribute to a longer operational life for the screens and other components.

- Best for Fine to Medium Grinding: Full-Screen mills excel in applications requiring fine to medium particle sizes with high throughput.

Our Full Screen Hammer Mill Data Sheet (PDF) provides more in-depth specifications for this design.

Gravity Discharge (Bottom Discharge) Mills

Gravity discharge mills represent one of the most straightforward industrial hammer mill designs. Once reduced to the desired size, material falls out of the mill's bottom discharge opening via gravity.

Key characteristics include:

- Simple Design: Their mechanical simplicity often means easier maintenance compared to more complex systems.

- Heavy-Duty Use: These mills are frequently chosen for processing dense, robust, or abrasive materials.

- Coarse Grinding: While they can achieve finer grinds, gravity discharge mills are often preferred for applications requiring coarser particle sizes.

- Ideal for Dense Materials: Materials like aggregates and minerals are well-suited for gravity discharge, as their weight aids their exit from the grinding chamber.

This type of mill is a powerful choice for many industrial crushing needs. Learn more in The Power of Hammer Mills.

Pneumatic and Air-Swept Mills

Pneumatic, or air-swept, hammer mills integrate an air system to assist in material discharge. Instead of relying on gravity, these mills use airflow to draw ground material through the screen.

- Fine Grinding: The continuous airflow helps clear screen openings, allowing for more efficient passage of very fine particles, making them excellent for producing fine powders.

- Cooling Action: The airflow also serves to cool the grinding chamber, which is crucial when processing heat-sensitive materials to prevent degradation.

- Integrated Dust Control: By incorporating an air system, these mills can be effectively connected to dust collection systems, minimizing airborne dust.

- Efficient Conveyance: The pneumatic system not only discharges the material but can also convey it to the next processing stage, which is beneficial for light or low-density materials.

When considering if a pneumatic system is right for you, our article Rotormills vs. Hammermills: Which is Right for You? offers valuable insights.

Key Selection Criteria for Your Application

Choosing the right industrial hammer mill is about a precise match between your material, your desired output, and the mill's capabilities. A mismatch can lead to inefficient processing, excessive wear, and inconsistent product quality. We approach selection as a partnership to ensure you get the optimal solution.

When we help you select a hammer mill, we consider several critical factors:

- Material Characteristics: This is paramount. We look at friability, moisture content, bulk density, and in-feed size. For instance, an abrasive material will require different hammer metallurgy than a soft, fibrous one.

- Desired Throughput: How much material do you need to process per hour or day? This directly influences the size and horsepower of the mill required, with rates from 10 lbs/hr to 10 tph or more.

- Target Particle Size: What is the exact finished particle size you need? This dictates the screen perforation size, rotor speed, and hammer configuration. We can often achieve particles smaller than 0.08" in size.

- Upstream and Downstream Equipment: Your hammer mill won't operate in isolation. We consider how material will be fed and collected for seamless integration.

For those in the feed industry, these considerations are vital. Our Guide to Selecting Hammer Mills for Feed Processing offers industry-specific insights.

Matching Mill Speed to Material

The rotor's rotational speed (RPM) is a fundamental control for achieving the desired particle size.

- Coarse Grinding RPMs: For applications requiring a coarser grind, such as reducing biomass, lower RPMs (1,500-1,800 rpm) are generally used.

- Fine Grinding RPMs: When a very fine powder is needed, higher RPMs (3,000-3,600 rpm) are used. The increased impact frequency leads to much finer particle reduction.

- Variable Frequency Drives (VFDs): Modern technology often incorporates VFDs. These allow operators to precisely adjust the rotor speed, offering flexibility to process different materials with the same mill.

Optimizing mill speed is crucial for processes like animal nutrition. Our expertise in Optimizing Animal Nutrition: Enhancing Grinding Efficiency highlights this balance.

Hammer and Screen Configuration

Beyond mill type and speed, the specific configuration of hammers and screens plays a pivotal role in performance.

- Hammer Types: Hammers come in various forms, including:

- Swinging Hammers: These are pivoted, allowing them to swing back if they encounter ungrindable objects, protecting the mill from damage.

- Rigid Blade Hammers: Fixed to the rotor, these provide a more aggressive impact and can achieve closer hammer-to-screen clearances for finer grinding.

- Hammer Patterns: The arrangement and number of hammers can be customized to optimize impact zones and material flow.

- Wear-Resistant Materials: Hammers and internal wear plates are often made from specialized alloys (e.g., hardened steel, chrome alloys) to withstand abrasion and extend their lifespan.

- Screen Hole Size and Shape: Screens are available with a vast array of hole sizes and shapes (round, square, slotted) to match the target particle size.

- Bar Grates: For very coarse grinding or processing tough, fibrous materials, solid bar grates may be used instead of perforated screens for greater durability.

The ability to quickly change screens is a significant advantage. We've created resources like Replacing the Screens on a Prater MM5 Megamill (Hammermill) to guide customers through this process.

Applications and Benefits Across Industries

The versatility of the industrial hammer mill is truly remarkable. It's a workhorse in countless sectors, efficiently reducing materials to precise specifications. This adaptability, combined with its inherent benefits, makes it an indispensable tool.

The key benefits our customers realize include:

- Versatility: Hammer mills can process a wide range of materials, from soft organic matter to harder minerals, both wet and dry.

- Cost-effectiveness: A relatively simple design means a lower initial investment and reduced long-term operational and maintenance costs.

- High Throughput: Designed for continuous operation, hammer mills can process large volumes of material rapidly.

- Uniform Product: Precise control over screen size and other parameters ensures a consistent particle size, which is critical for product quality.

- Simple Operation: Operating a hammer mill is generally straightforward, making them easy to integrate into existing production lines.

- Energy Savings: Advanced designs with patented closed rotor configurations can achieve energy savings up to 20% compared to traditional models.

These advantages highlight why hammer mills are essential for quality production. Explore more in Why Hammer Mills Are Essential for Quality Production.

Common Industries and Materials

Our experience shows that the industrial hammer mill is a powerhouse serving a diverse range of industries:

- Agriculture: Grinding grains (corn, wheat), feed for livestock, and crop residues to ensure optimal digestibility.

- Biofuels: Processing biomass materials like wood chips and agricultural waste into a consistent size for pelletizing or gasification.

- Food Processing: Grinding spices, sugar, coffee beans, and other ingredients to precise particle sizes.

- Chemicals: Reducing various chemical compounds, pigments, and resins to fine powders for mixing or packaging.

- Minerals: Crushing gypsum, limestone, clay, and coal for use in construction, manufacturing, and energy production.

- Recycling: Grinding materials like paper, plastics, and light scrap fiberglass to prepare them for reuse.

This wide array of applications underscores the machine's adaptability. For a comprehensive look, see Versatility of Hammer Mills: Industrial Powerhouse for Every Industry.

Specialized Applications

Beyond common uses, industrial hammer mills are critical in several specialized applications:

- E-waste Recycling: Hammer mills shred electronic waste like printed circuit boards, helping to liberate valuable metals for recovery.

- Biofuel Production from Biomass: They are vital for preparing diverse biomass feedstocks for conversion into biofuels, ensuring efficient downstream processing.

- Spice and Herb Grinding: In the food and pharmaceutical industries, mills grind dried spices and herbs to various fineness levels, preserving their flavor and active compounds.

- De-agglomeration: Hammer mills can effectively break down clumped materials, changing them back into free-flowing powders. This is essential for rework or conditioning materials that have caked during storage.

These examples showcase how a well-configured industrial hammer mill can address unique and demanding processing challenges. Learn more in How Are Biofuels Made with Hammermills.

Maintenance, Safety, and Modern Advancements

Even the most robust industrial hammer mill requires diligent care to ensure continuous, efficient, and safe operation. We've refined our approach to maintenance and safety while embracing technological advancements that make these mills more intelligent and user-friendly.

Routine maintenance for an industrial hammer mill typically involves:

- Inspection of Wear Parts: Regularly check hammers, screens, and internal liner plates for wear. Proactive replacement prevents breakdowns and maintains efficiency.

- Bearing Lubrication: Proper lubrication of the rotor bearings is essential for smooth operation. We offer guidance in resources like Hammermill Bearings Maintenance (Prater G Series).

- Cleaning: Regular cleaning of the grinding chamber and screens prevents material buildup and maintains product quality.

Safety is paramount. Modern industrial hammer mills incorporate several features to protect operators:

- Safety Interlocks: These systems prevent the mill from operating if access doors are open.

- Dust Collection Systems: Integrated dust collection is vital to manage airborne particles, improving air quality and reducing explosion hazards.

- Emergency Stops: Clearly marked and accessible emergency stop buttons allow for immediate shutdown.

Peripheral Equipment for a Complete System

To create a fully functional system, a hammer mill is often integrated with peripheral equipment:

- Feeders: These control the material in-feed rate to ensure consistent processing and prevent overloading.

- Magnetic Separators: Installed upstream, these remove ferrous tramp metal from the material stream, protecting the mill from damage.

- Conveyors: These systems transport raw material to the mill and move the finished product away.

- Air Systems: For pneumatic mills, this includes fans and ductwork to draw material through and convey it.

- Cyclones and Collection Bins: These separate the ground product from the airflow in pneumatic systems, depositing it into collection bins.

Designing a complete system requires careful integration. Our expertise helps optimize performance, as highlighted in Modern Hammer Mill Technology for Efficient Processing.

Innovations in Hammer Mill Technology

The industrial hammer mill is a long-standing technology, but it's far from static. Continuous innovation has led to significant advancements:

- Automated Controls and Advanced Monitoring Systems: Modern mills feature PLCs that allow for precise adjustments. Advanced monitoring systems track metrics like temperature and vibration in real-time, enabling predictive maintenance.

- Variable Frequency Drives (VFDs): VFDs provide dynamic control over rotor speed, offering flexibility to adapt to different materials without mechanical changes.

- Improved Wear-Resistant Alloys: Ongoing metallurgical research has led to tougher, more durable materials for hammers and screens, extending component lifespan.

- Sanitary Designs: For industries like food and pharmaceuticals, mills are available with sanitary designs that meet stringent standards (e.g., FSMA, 3A/Dairy) with features like stainless steel construction and easy-to-clean access.

- Energy Efficiency: Innovations like patented closed rotor designs have improved energy efficiency, leading to power savings of up to 20%.

These advancements ensure that today's industrial hammer mill is more efficient and reliable than ever. Find our latest offerings on our page on Hammer Mills.

Conclusion

Choosing an industrial hammer mill is easier when you understand the core principles. We've covered how they work through high-speed impact, the differences between Full-Screen, Gravity Discharge, and Pneumatic mills, and how to select the right one for your needs.

The right selection hinges on analyzing your material, throughput, and target particle size, then optimizing mill speed, hammer type, and screen configuration. The benefits are clear: versatility, cost-effectiveness, and uniform product quality across industries from agriculture to recycling.

A robust design, diligent maintenance, and modern technology ensure long-term value. With over 90 years of experience, Prater Industries provides low-maintenance, reliable particle reduction solutions customized to your needs. We're here to help you find the perfect match for your material, ensuring your operations run smoothly.

Ready to find the ideal solution for your processing needs? Explore our full range of industrial hammer mills to find the perfect solution for your operation.