Precision Powders: Enhancing Efficiency in Ultra-Fine Classification

The Critical Role of Particle Size in Modern Industry Fine powder classification is the process of ...

Read More>

A Comprehensive Guide to Rotary Sifter Applications

Understanding Rotary Sifter Applications in Industrial Processing A rotary sifter is a ...

Read More>

Industrial Hammer Mill Comparison 101

Why Choosing the Right Industrial Hammer Mill Matters An industrial hammer mill is a high-impact ...

Read More>

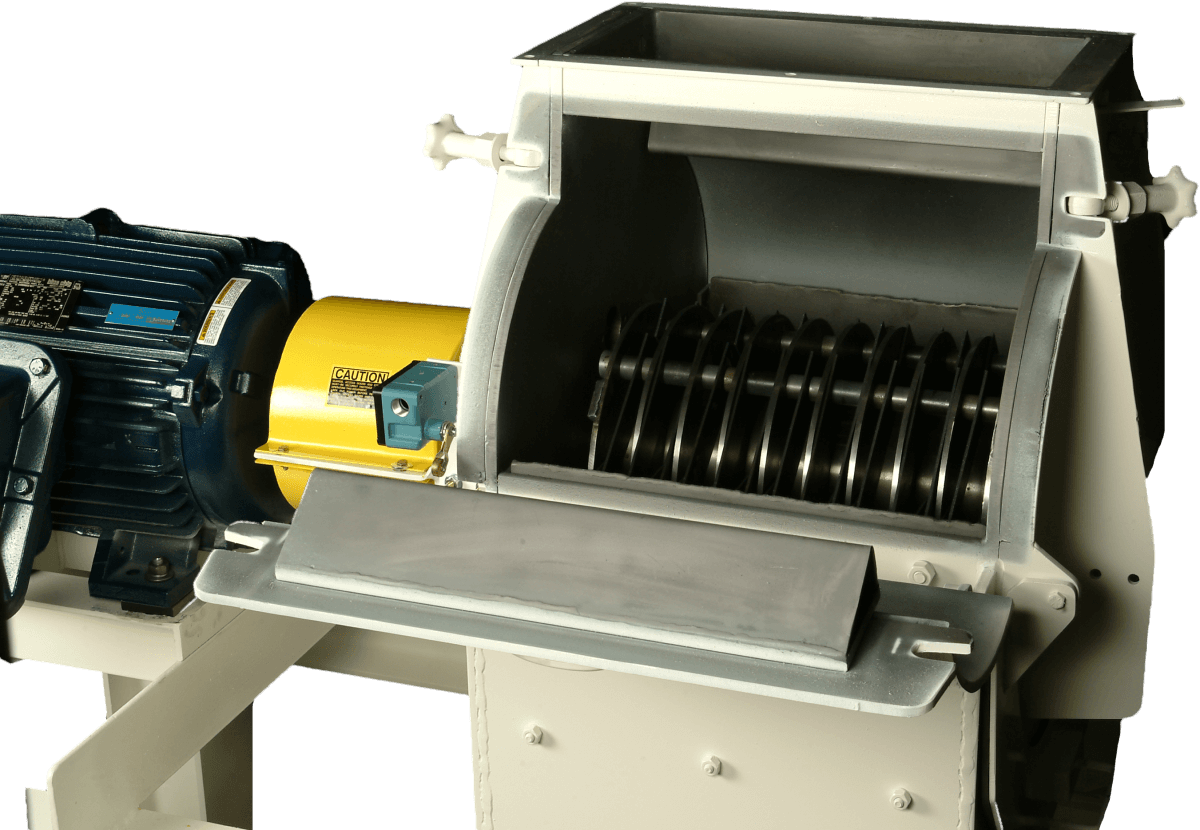

Industrial Lump Breakers: Improve Material Flow & Efficiency

Why Industrial Lump Breakers Matter for Your Process Industrial lump breakers solve one of the most ...

Read More>

Celebrating 100 Years of Prater Industries

This year, Prater Industries proudly marks a monumental achievement—our 100th anniversary. Since ...

Read More>

Applications for Centrifugal Sifters

Known also as rotary sieves, rotary sifters or rotary screeners, centrifugal sifters are a type of ...

Read More>

Innovations in Hammer Mill Machinery

With iterations used by humanity for millennia, hammer mills have advanced considerably over time. ...

Read More>

Controlling Bulk Material Flow from Storage Containers

It’s important to design feeders and hoppers so that bulk material flows properly during the ...

Read More>

Food Grade Applications for Diatomaceous Earth

The fossilized remains of single-celled algae called diatoms are largely what make up the powdery ...

Read More>

Attrition Milling & Why It is Used in the Pharmaceutical Sector?

Physics refers to the gradual grinding down or wearing away of material through abrasion or ...

Read More>